Value Added Products |

| |

• Pick & Place Equipment

• Assembly Line Automation

• Robotic Based Applications

• Ultra Sonic Cleaning Machine

• Vision Camera inspection Machine

• Fixtures, Dies

|

| |

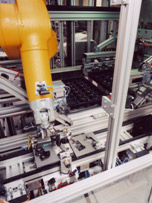

Robotic Integrated System - HA Model

|

| |

|

| |

HA Model builds and integrates robotic systems for your precise and high-speed applications. We offer robotic systems (2,3,4 axis) made from combinations of linear slides and rotary actuators to handle part placement, stacking, machining, inspection, welding, and much more.

|

| |

Industrial robots, especially six-axis robots, provide flexibility and dexterity which is unsurpassable for some operations. The true worth of a robot is realized only when it is integrated with our HA feeding equipment and tooling in a production cell.

|

|

At HA Model we have experience in integrating robots from a number of different manufacturers in a variety of applications which includes installation & programming support for application such as: |

| |

Loading / unloading assembly and test machines

Applying adhesives, sealants and surface preparation agents.

Handling products to / from packaging

Assembly operations.

Laser welding.

Furnance Loading & Unloading

Articulated Part Placement & Positioning

Articulated Part Positioning

Inspection & Verification |

| |

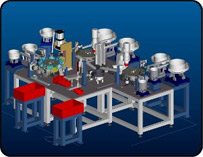

Assembly Line Automation - HA Model

|

| |

|

|

|

|

| |

inspection can be integrated on the machines. Components can be secured by the application of adhesives, welding, ultrasonic or induction sealing. We can also incorporate slitting, drilling, tapping or screw stations. |

| |

Such SPM Includes: |

| |

1) Lipstick Assembly Machine

2) Writing Instrument Assembly Machine |

| |

Single Source Responsibility |

| |

We provide a complete solution by integrating our proprietary feeder bowls to position the parts to be assembled, along with a vision system that qualifies acceptable & defective assembled parts before being packed. In this way, we take full responsibility to deliver a fully tested and functional turnkey system that feeds, positions, assemble, inspect and pack the final marketable products. |

| |

We have successfully installed assembly lines, on pan India basis, for the Plastics, Metals, Medical Devices, Writing Instruments and Cosmetics & Personal Care industries. Some examples include powder & eye shadow compacts, lipsticks, mascaras, lip-gloss tubes.

|